SPRINGS

Aligent Spring can design and manufacture almost any kind of spring and wire forming. Our range includes the broad categories of compression, extension and torsion springs, and wire and strip forming made from ferrous and non-ferrous, round and shaped wires and strips. The combination of the different materials and designs are almost endless to describe but generally we are equipped to handle wire sizes equivalent from Ø0.05mm to 8.00mm.Compression Spring

Compression springs are open-coil helical springs that provide resistance when compressed. They are usually coiled in a constant diameter in Cylindrical, Conical, Barrel, Hourglass, Variable Pitch or other various combinations according to the application.

The spring ends can be closed & ground, closed & unground, open & ground, as well as open & unground. The most common type of spring end is closed & unground type.

Round wires are quite commonly used in compression springs as the standard coiler tooling is easily available. Unlike square wire, rectangular wire or other special shaped wire, may have to specify and customize tooling is required for the machine.

The most commonly used materials for Compression springs are mainly the Carbon Steel and Stainless Steel. And in some cases, Phosphor Bronze, Brass, Beryllium Copper, and other special material are also available.

Aligent spring can manufacture compression spring in wire diameter of:

- 0.05mm - 0.40mm with unground ends

- 0.40mm - 5.00mm with ground ends as per request

Spring Rate Calculation

K = Gd^4/8naD^3

Example: (78000N/mm^² x Wire Diameter^4) ÷ (8 x Active Coils x Mean Diameter^³)

N = No. of Total Coils

D = Mean Diameter

na = Active Coils

d = Wire Diameter

E = Young's Modulus of Material

G = Shear Modulus of Material

- G-Rigidity Modulus for SWC (JIS 3521 Class C) / SWP (JIS 3522 Class A/ B) = 78000N/mm^²

- G-Rigidity Modulus for SUS 304 WPB (JIS 4314 Class B) = 69000N/mm^²

Extension Spring

Extension springs are close-coiled helical spring which will extend under a pulling force. The common ends or hooks manufactured by Aligent Spring are: English hook, German hook, Extended hook, Side hook, and various type of ends according to customers’ designs and applications.

And common extension springs are manufactured from round wire and are close wound with initial tension which offers a small deflection load for secured installation. Round wire is commonly used in extension spring as the standard coiler tooling is easily available. The most commonly used materials for Extension springs are mainly the Carbon Steel and Stainless Steel. And in some cases, Phosphor Bronze, Brass, Beryllium Copper, and other special material are also available.

Aligent Spring can manufacture extension spring in wire diameter of:

- 0.15mm - 1.00mm with standard English hook

- 0.15mm - 3.80mm with German hook or English hook as per request

Torsion Spring

Torsion springs have ends which can be rotated in angular deflection and offer resistance to the externally applied torque. This spring is normally available in closed wound but the open pitch spring is also available to reduce the friction between coils.

Double torsion spring is a unique type of torsion spring which consists of two sided coils (left hand coil and right hand coil). The two sided coils are connected and worked in parallel position. The configuration of torsion spring is varied widely according to the end application.

Round wire is commonly used in Torsion spring as the standard coiler tooling is easily available. Unlike square wire, rectangular wire or other special shaped wire may have to specify and customize tooling is required for the machine.

The most commonly used materials for Torsion springs are mainly the Carbon Steel and Stainless Steel. And in some cases, Phosphor Bronze, Brass, Beryllium Copper, and other special material are also available.

Aligent spring can manufacture torsion spring in wire diameter of:

- 0.10mm - 4.00mm round wire

- shaped wire as per request

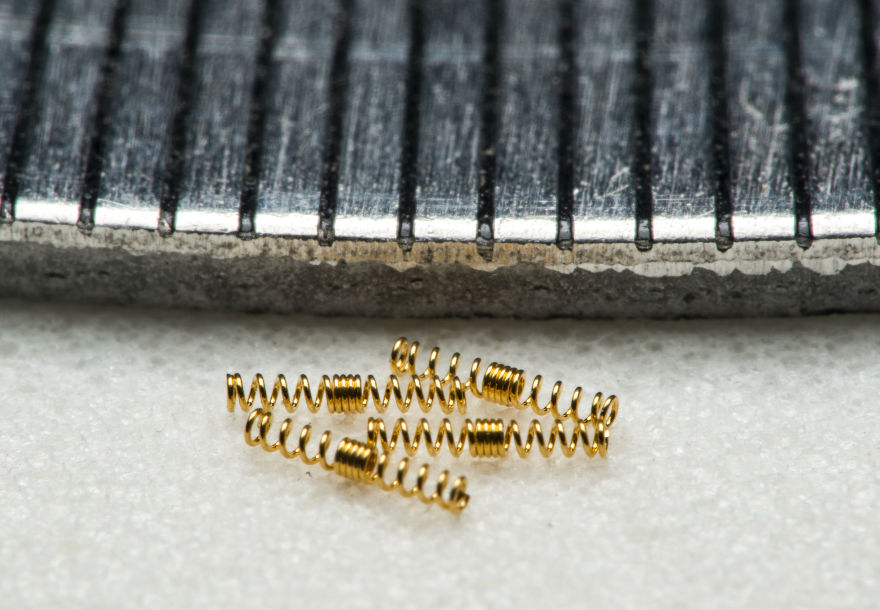

Micro Spring

Micro springs are open-coil helical springs that provide resistance when compressed. They are usually coiled in a constant diameter in Cylindrical, Conical, Barrel, Hourglass, Variable Pitch or other various combinations according to the application.

The most common type of spring end is the closed and unground end.

Round wire is commonly used in Micro spring as the standard coiler tooling is easily available. Unlike other special type of wire size, may have to specify and customize tooling is required for the machine.

The most commonly used materials for Micro springs are mainly the Carbon Steel and Stainless Steel. And in some cases, Phosphor Bronze, Brass, Beryllium Copper, and other special material are also available.

Aligent spring can manufacture micro spring in wire diameter of:

- 0.05mm - 0.30mm with unground end

Battery Contact Spring

Battery spring works in 2 functions: (1) providing pressure to hold the battery sitting in place and (2) allowing electrical current flowing to the circuit.

We have a range of fully equipped machines for production. At times, customized tooling is required due to special or complicated design. There is no standard design and in Aligent, we can custom-made any battery spring to suit your application as well as design needs.

The most commonly used materials for Battery springs are mainly the Carbon Steel and Stainless Steel. And in some cases, Phosphor Bronze, Brass, Beryllium Copper, and other special material are also available.

Aligent spring can manufacture battery spring in wire diameter of:

- 0.15mm – 3.00mm round wire according to the battery design

Wire Form

Wire form may have various function or application and there is no standard design.

We have a range of fully equipped machines for production. At times, customized tooling is required due to special or complicated design. In Aligent, we provide consultancy services, such as design queries and offer suggestions on how to optimize cost savings on part cost at no obligation.

The most commonly used materials for Wire form are mainly the Carbon Steel and Stainless Steel. And in some cases, Phosphor Bronze, Brass, Beryllium Copper, and other special material are also available.

Aligent spring can manufacture wire forms in wire diameter of:

- 0.10mm - 4.00mm full hard round wire

- up to 8.00mm of soft wire (low carbon steel)

- shaped wire as per request